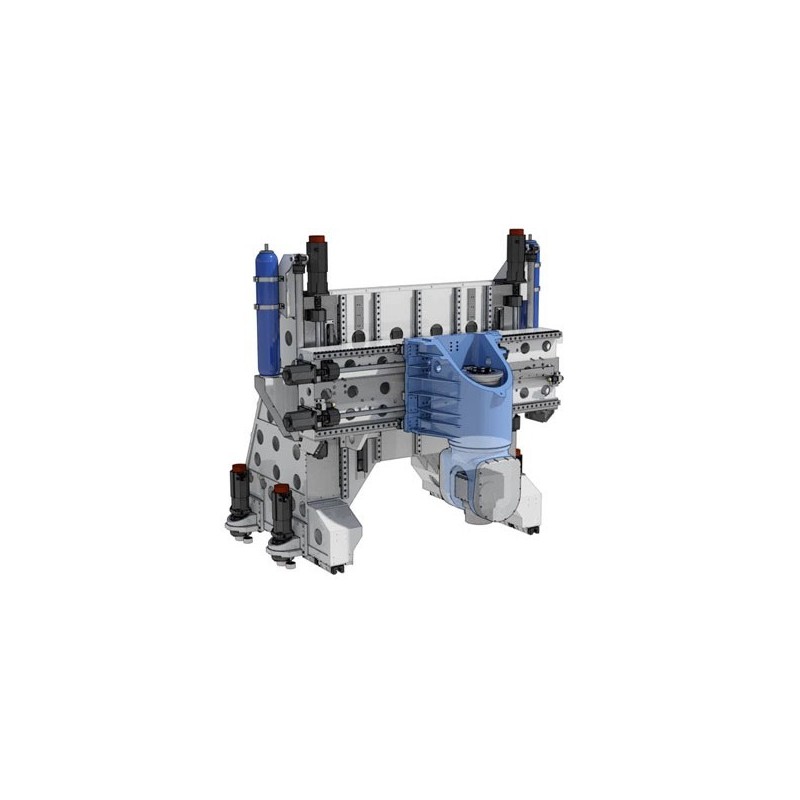

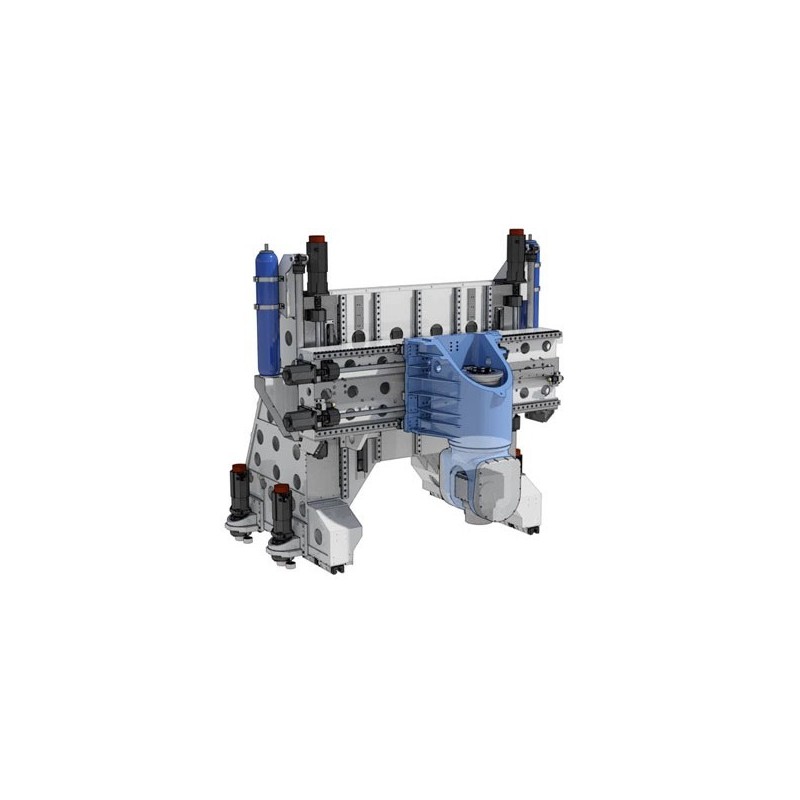

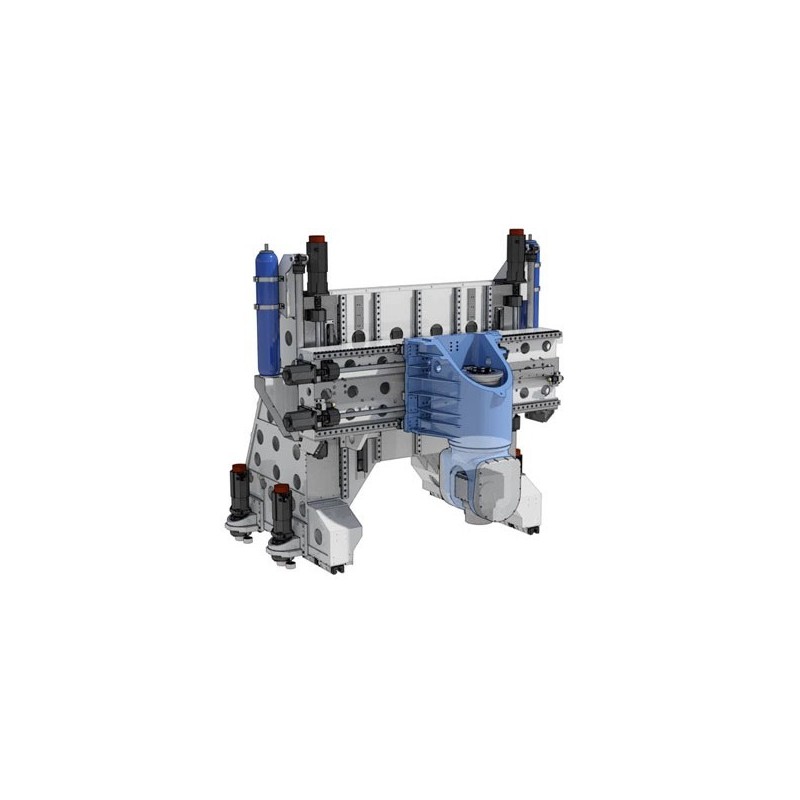

RigiMill, long bed machining – two different machines on one bed, configured with the customized gantries you require for milling aluminum or titanium. Our footprint occupies one-third less space than other gantries. Cycle time is reduced 30-50%.

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Long bed machining with RigiMill – The market’s first “two in one” machine for heavy machining in titanium.

For the first time ever it is possible to operate one machine for optimal roughing and optimal finishing.

RigiMill, long bed machining – two different machines on one bed, configured with the customized gantries you require for milling aluminum or titanium. Our footprint occupies one-third less space than other gantries. Cycle time is reduced 30-50%.

Just think what that does to optimize productivity and reduce tooling costs. Per minute chip removal rates up to 55 cubic inches in titanium and 850 cubic inches in aluminum make this machine a world leader.

The all new RigiMill summarizes much of the spirit and ambition that keep us going here at Modig. Developing and producing high-tech machining solutions at the frontline of what´s possible always with the benefit of our clients in our mind – That´s what it is all about, and that is what RigiMill exemplifies.

Data sheet