The MCC2013-VG HMC is the complete package for high-efficiency mold machining.

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

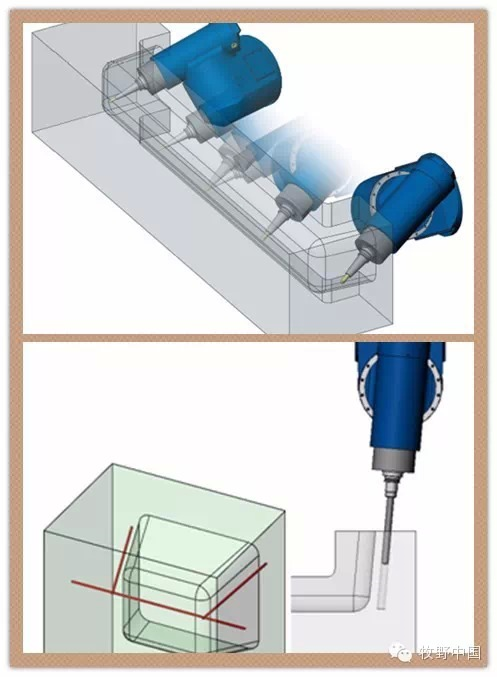

The MCC2013-VG HMC is the complete package for high-efficiency mold machining. Standard curvic coupling A & C rotary axes allow the spindle to be tilted for optimal accessibility to complex mold cavity features. The MCC2013-VG is actually a 6-axis machine that includes a B-axis rotary table. This facilitates 5 sided machining in a single setup, helping to eliminate multiple operations. Additional productivity boosting features include a high-speed 12,000 min-1 spindle, 20m/min cutting feedrate, high-speed, high-accuracy Super GI.4 control and a thermal stability system. The MCC’s feature a semi-floating slideway system to provides highly accurate positioning and vibration free contour machining at feedrates up to 20 m/min, even with heavy work pieces on the table. The standard of 0.1µm GI.4 control substantially improves mold machining accuracy and surface quality.

Effects of Thermal Changes in Die/Mold applications

Many machine tool manufacturers address the generation of heat during long machining operations in different ways. Some are far more effective than others. In this webinar you will learn about unique technologies designed to address the challenges of thermal growth on die and mold machining applications. Specific data and test results will demonstrate the effects of thermal growth and its impact on work surfaces and how it can be managed and controlled to insure accuracy and finish.

Data sheet