K-Scan MMDx is Nikon Metrology's walk-around laser scanner for portable metrology applications. The MMDx scanner is renowned for its accuracy, easy-to-use and stunning performance.

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

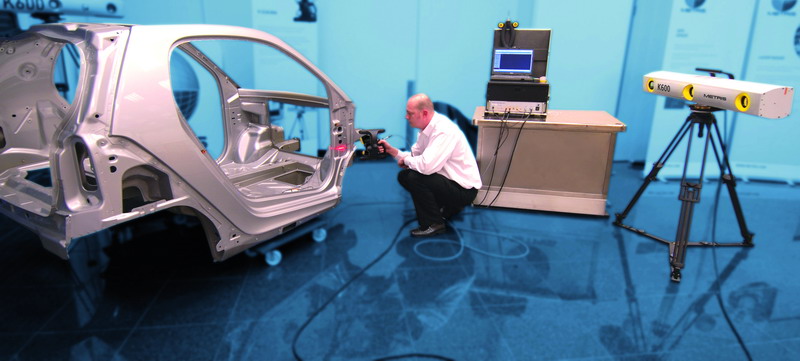

K-Scan MMDx is Nikon Metrology's walk-around laser scanner for portable metrology applications. The MMDx scanner is renowned for its accuracy, easy-to-use and stunning performance. The scanner is tracked by the K-Series Optical CMM, so that operators can take scans anywhere needed. K-Scan MMDx is the ultimate tool for accurate part-to-CAD inspection and productive reverse engineering. It combines the accuracy and productivity of the MMDx laser scanner with the operator freedom, measurement volume and motion compensation of the K-Series Optical CMM.

Key benefits

Categories: Handheld scanning

Applications: Automotive Design and Styling, Pilot Plant Metrology, Flush and Gap Inspection, Full Vehicle Inspection, Aftermarkets

K-Scan MMDx’s portability, accuracy and large measurement volume are responsible for the system’s high application reach. The absence of mechanical constraints creates superior operator comfort, which allows operators to efficiently take scans in and around an entire vehicle or truck. For measuring larger objects, the system supports the use of magnetic reference spheres to leap frog measurements taken from multiple camera standpoints. Regardless of how and where to use the system, it serves both inspection and reverse engineering applications.

ESP3 incorporates dynamic point-per-point laser intensity adaptation of laser source intensity. This capability allows different surface materials, finishes and transitions to be scanned without user interaction, eliminating manual parameter tuning and part spraying altogether. ESP is a key differentiator when scanning similar parts in different manufacturing stages; initially dealing with bare sheet metal parts and finally scanning finished products painted in any color.

The digital camera technology built in the scanner supports high-resolution data acquisition and processing for scanning freeform surfaces and features accurately and efficiently. Continuous and precise optical probe tracking are maintained by optimizing the positions of the LEDs integrated into the scanner housing.

Featuring a high frame rate and a laser stripe up to 200mm, the digital MMDx scanner provides the ultimate in scanning productivity. The digital camera technology built in the scanner supports high-resolution data acquisition and processing for scanning freeform surfaces and features accurately and efficiently. MMDx laser scanners come in 50, 100 and 200 millimeter laser stripe widths, to suit every measurement need.

An effortless scanning experience is made possible by the ergonomic handgrip of the scanner and the unmatched ease-of-use of the system’s optical CMM. The operator can simple walk around and scan surfaces as desired, without facing the limitations of any mechanical constraints. Measuring has never been easier, thanks to the scanner’s balanced handgrip, carbon fiber design and feedback indicators.

K-Scan MMDx is a truly portable solution that can be used anywhere. It can be set up instantly in the laboratory, on the shop floor or in the field. The Optical CMM automatically localizes the light-weight, handheld MMDx laser scanner. Dynamic object referencing ensures accurate measurement in case the measured object is moved.