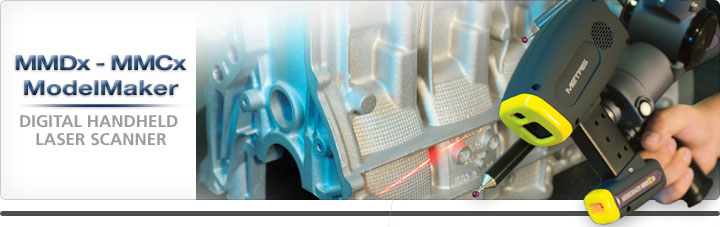

The ModelMaker MMCx / MMCx handheld laser scanners offer high value at affordable cost. These all-purpose scanners are ideally suited for portable 3D inspection and reverse engineering applications where the unmatched capability of the ModelMaker to scan any surface meets the need for a budget-friendly solution.

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Scaner laser ModelMaker MMDx pentru echipamente portabile, in vederea efectuarii inpectiei 3D si procedeului de Revers Eng.

The ModelMaker MMCx handheld laser scanners offer high value at affordable cost. These all-purpose scanners are ideally suited for portable 3D inspection and reverse engineering applications where the unmatched capability of the ModelMaker to scan any surface meets the need for a budget-friendly solution.

Its camera technology introduces an adequate frame rate and a stripe width up to 160mm. MMCx features Enhanced Sensor Performance (ESP3) to eliminate user interaction when scanning different sample materials and surface finishes.

Categories: Handheld scanning

Applications: Automotive Design and Styling, Pilot Plant Metrology, Die and Mould Applications, Aftermarkets

The digital camera offers a measuring accuracy down to 12 micron (MMCx40) and benefits from a high true non-interpolated resolution, allowing freeform surfaces and features to be scanned accurately and efficiently.

Measuring soft and fragile parts potentially yield inaccurate measurements or surface scratches. As laser scanning technology is entirely non-contact, there is no risk for damage or inaccurate measurement.

The ModelMaker MMxC laser scanner offers a sufficient scan rate and a laser stripe with adequate point density. This ensures that freeform shapes and geometric features can be digitized efficiently. Surface and feature shapes are critical for high-quality assembly and part mating.

ESP3 incorporates dynamic point-per-point laser intensity adaptation of laser source intensity. This capability allows different surface materials, finishes and transitions to be scanned without user interaction, eliminating manual parameter tuning and part spraying altogether. ESP is a key differentiator when scanning similar parts in different manufacturing stages; initially dealing with bare sheet metal parts and finally scanning finished products painted in any color.

The ModelMaker MMCx is compatible with MCA II series and many 3rd party articulated arms.

The ModelMaker MMCx laser scanner interfaces directly using the Ethernet connection with the laptop. There is no need for a controller interface and it can be used instantly after unpacking.

|

|

MMDx50 |

MMDx100 |

MMDx200 |

MMCx80 |

MMCx160 |

|

Stripe Width(Y) |

50mm(2.0 in.) |

100mm(3.9 in.) |

200mm(7.9 in.) |

80mm ( 3.1 in.) |

160mm (6.3 in.) |

|

Stand-off (to near FOV) |

95mm(3.7 in.) |

100mm(3.9 in.) |

110mm( 5.9 in.) |

100mm(3.9 in.) |

110mm(4.3 in.) |

|

Measuring range (z) |

50mm(2.0 in.) |

100mm( 3.9 in.) |

150mm (5.9 in.) |

100mm(3.9 in.) |

150mm(5.9 in.) |

|

Accuracy |

7um |

10um |

16um |

16um |

23um |

|

Date rate at full FOV |

50Hz |

60Hz |

30Hz |

||

|

Max. date rate |

150Hz |

30Hz |

|||

|

Points per stripe |

1000 |

800 |

|||

|

Temperature compensation |

Yes |

No |

|||

|

Laser power control |

Fully automatic – per point(Enhanced sensor performance – ESP3) |

||||

|

Sensor weight |

Approx 400g(14.1 oz.) |

||||

|

Laser power |

Class 2 |

||||

|

Localiser compatibility |

Nikon Metrology MCAx/MCA II 7-axis/MCA 7-axis(v2.2 & 2.5) Nikon Metrology K-series K600/K610 Romer/CimCore Infinite 1.0SC 7-axis/Infinitte 2.0SC 7-axis Faro platinum/Titanium/Fusion 7-axis |

||||