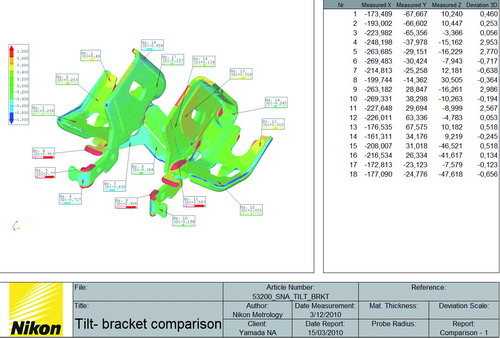

Focus Inspection is today’s reference for point cloud inspection. It manages acquired point clouds and performs part-to-CAD comparison and advanced feature inspection.

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Focus Inspection is today’s reference for point cloud inspection. It manages acquired point clouds and performs part-to-CAD comparison and advanced feature inspection. The software covers a wide range of inspection applications and offers stunning performance, an intuitive user interface, and standard macro functionality to automate the entire inspection process.

Focus 10.1 SP1 VIEWER (exe-file, 60Mb)

Focus 10.1 SP1 VIEWER x64 (exe-file, 73Mb)

Focus 10.1 VIEWER (exe-file, 59Mb)

Focus 10.1 VIEWER x64 (exe-file, 70Mb)

Focus 10 VIEWER (exe-file, 59Mb)

Focus 10 VIEWER x64 (exe-file, 63Mb)

Categories: Point cloud software

Applications: Implants/Protheses, Flush and Gap Inspection, Die and Mould Applications, Sheet Metal Inspection, Powertrain Components, Automotive Components Inspection, Full Vehicle Inspection, Aftermarkets, Mobile phones, shavers & watches , Household appliances and white goods , Cosmetics, Turbine Blade Inspection

.jpg)

Focus 10 presents a new user interface featuring a Windows-7 style ribbon toolbar, where users will feel at ease immediately.

Focus 10 offers tightly integrated data acquisition – via CMM or handheld scanners – and intelligent processing and reporting. Direct access to workflow selection, customization and automation facilitate the setup and execution of processing jobs. Focus 10 drives seamlessly latest-generation Nikon Metrology CMM and handheld laser scanners, and supports many CMM and articulated arm brands.

.jpg)

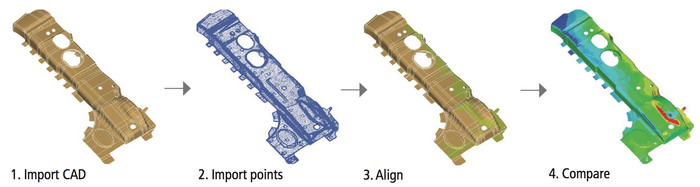

Digitizing components up-front and running inspection on the digital copies of the samples, streamlines metrology operations and embeds them into the digital CAD-centric development process. As a Digital Inspection Process provides more profound metrology insight, it is essential to improve and accelerate styling, tooling, prototyping and series production.

The user interface is workflow-oriented to minimize the number of clicks required to move from point clouds to graphic geometry reports. Focus allows engineers to tune the process exactly as desired, whereas operators easily manage and run inspection jobs. During measurement, they monitor the inspection progress and outcome using real time graphic and numerical result displays.

Focus Inspection offers the possibility to read product manufacturing information (PMI) from the CAD file. Using this information, features are retrieved automatically from the point cloud and evaluated to their tolerances. This eliminates the error prone and time consuming entry of dimensions and tolerances. The creation of the inspection program by teach in does not require any programming skills.

Freeform surfaces:

.jpg)

Geometric features: