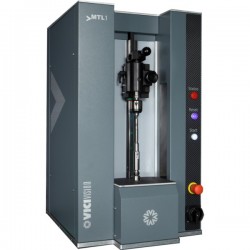

MTL X1 has a wider measuring range (300x60 mm), in a compact and practical machine used to analyze and measure the castings. Its unique design offers direct access to the track, providing a practical loading both for small and large component.

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

MTL X1 has a wider measuring range (300x60 mm), in a compact and practical machine used to analyze and measure the castings. Its unique design offers direct access to the track, providing a practical loading both for small and for large compenenta.

It has a full metal housing that provides protective equipment in the work environment.

The vertical position facilitates loading of the piece, even for parts up to 300 mm length, using special mounting systems.

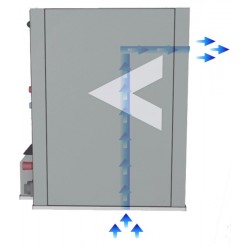

The machine is equipped with a dual temperature compensation (both diameters and lengths), ideal for use directly in the production hall. Unique cooling system "Air Flow" makes this car stand and work in the toughest environments.

Displaying results in seconds

Measurement results are displayed on histograms for immediate consultation.

Faster and more accurate

MTL X1 projector functions include profiles, micrometers, roundness, eliminating human errors in obtaining measurements and enabling operators to manage data acquired.

Static Measurements: diameters, lengths, angles, radii, distances and angles between points and lines diameter sphere

Measurements geometric symmetry, parallelism, orthogonality

Measurements thread: nominal diameters, internal diameters, mean diameters, angles, heights, sizes roll

Measurements of the form Rotation diameters, roundness, coaxiality, cylindricity, angular measurements

DXF comparison (optional): the distance between the profiles, distances from tolerance, GD & T

Traditional measurement system

Measurements lasts between 10 and 30 minutes.

The data are influenced by the operator.

Hardly used.

Require the collection of data in manually.

Vici Vision measuring system

Measurements last 30 to 60 seconds.

It eliminates human errors.

Automatic measurement cycle by pressing a single button.

Collect data automatically.

Designed to increase production

MTL X1 is a video measuring machine castings, being able to measure parts in seconds directly in the production hall.

- Saves time by up to one hour for each batch of parts.

- Reduce downtime due to immediate control of parts.

Software with advanced features

Auto-programming: scans and performs all known geometric measurements automatically.

Aided Software: software automatically suggests measurements

Programming Manual: the operator can choose and change the measurements manually

Loading automatic program: MTL X1 is able to automatically recognize the song that is measured and load previously created program

Choose the best equipment to analyze the produced parts.

• Connectors fluid fittings • • • Parts type ax

• Parts multi-axis • Precision Screws Pini • • • Rivets • Screws rolled

• Screws and bolts • Casting •

• Casting electrical components •

• pinion shafts • Valves • Valves • Pistons hydraulic •

• Valves • Pneumatic Cylinders • • Turned Parts

• Dental Implants • shafts • Gears • Screws •

• Medical • Turbines • Screw compressors Turbo camshafts • •

• Clock • Parts

• Burners • Crankshaft • • Auto Axles