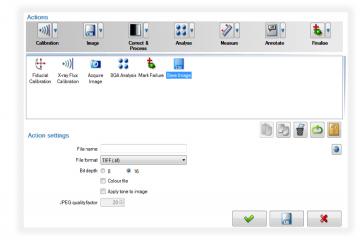

INSPECT-X 4.1 is the latest version of the software acquisition and analysis systems range Nikon Metrology X-ray and CT images in real time and offers improved and advanced analytics BGA.

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de securitate (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de livrare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

Politica de returnare (editeaza cu modulul Reasigurare pentru clienti)

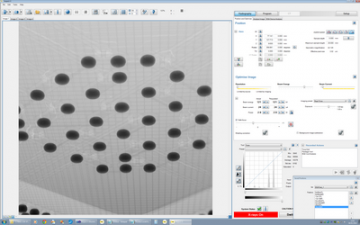

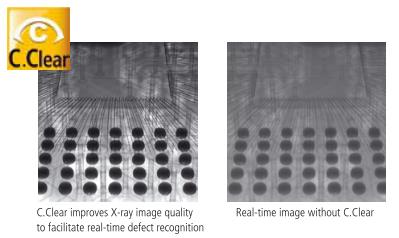

C.Clear intelligently adapts to changing X-ray conditions and sample positions, automatically adjusting image controls, contrast and brightness in order to provide the clearest and sharpest images to aid in defect recognition. Real-time enhancements and filters can be chosen and stored as user profiles to suit different sample types or individual operator preferences.

With C.Clear, operators can make fast and well-informed decisions, enabling defects to be detected correctly first time, especially for hard to detect faults within multi-tier BGA or complex bond wires. The C.Clear imaging engine enables manufacturers to increase inspection throughput and to reduce false call rates, leading to improved quality and efficiency.

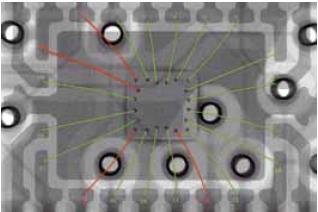

The new BGA tool provides powerful image processing, fully automated analysis and detailed reporting to inspect complex packages such as Package on Package (PoP) or dual-layered boards. With its powerful image processing algorithm, the tool gives accurate results even in complex board assemblies with underside components. The tool allows creation of an internal library of bGA templates using a wizard or via file import to reduce the time taken to build automated pass/fail inspection routines.

The BGA device inspection functionality is an ‘all-in-one’ tool offering automatic analysis of:

Operating in automated inspection mode, the XT V combined with Inspect-X is a productive X-ray solution for repeated inspection of PCBAs, semiconductor components and complex high density boards. Creation and execution of inspection routines is straightforward, utilizing the graphical interface or teach and learn.